Induction Motor Braking

The braking is the

process of stop or reduce the speed of running motor. In this braking operation

motor developing negative torque which oppose to motion of the motor. The

braking of induction motor is classified into three types.

1. Regenerative Braking

2. Plugging or Reverse Voltage Braking

3.

Dynamic Braking

·

AC Dynamic Braking

·

Self-Dynamic

Braking

·

DC Dynamic Braking

· Zero Sequence Braking

The braking of induction motor explained

below in details:

1. Regenerative Braking :

Input Power of motor induction motor is given by following formula:

Pin = 3*V*Is*CosØs

Where,

Pin

= Input Power of induction motor

V = Input Voltage

Is = Stator Current

CosØs = Phase angle between stator phase voltage & stator current

For motoring operation, the phase angle is always less than 90⁰. If the rotor speed becomes greater than synchronous speed, then the relative speed between the rotor conductor and air gap rotating field reverse. This reverse the rotor induces emf, rotor current and component of stator current which balances the rotor ampere turns. When the φs is greater than the 90º, then the power flow to reverse and gives the regenerative braking. The magnetizing current produced the air gap flux.

The nature of the speed torque curve is shown in the figure above. When the supply frequency is fixed, the regenerative braking is possible only for speeds greater than synchronous speed. With a variable frequency speed, it cannot be obtained for speed below synchronous speed.The main advantage of regenerative braking is that the generated power is fully used. And the main drawback is that when fed from a constant frequency source the motor cannot employ below synchronous speed.

2. Plugging or Reverse Voltage Braking :

When the phase sequence of supply of the motor running at speed is

reversed by interchanging the connection of any two phases of the stator on the

supply terminal, operation change from motoring to plugging as shown in the

figure below. Plugging is the extension of motoring characteristic for a

negative phase sequence from quadrant third to second. The reversal of phase

sequence reverses the direction of a rotating field.

§ AC Dynamic Braking : The dynamic braking is obtained when the motor is run on the

single phase supply by disconnecting the one phase from the source and either

leaving it open or connecting it with another phase. The two connections are

respectively known as two and three lead connection.

When connected to a one phase supply the motor can be considered as to

be fed by positive and negative sequence three phase set of voltage. The total

torque produced by the machine is the sum of torque due to positive and

negative sequence voltage. When the rotor has high resistance, then the net

torque is negative, and the braking operation is obtained.

§ Self-Excited Braking Using Capacitor: In this method the three

capacitors are permanently connected to the motor. The value of the capacitor

is so chosen that when disconnecting from the line, the motor works as a

self-excited induction generator. The braking connection and self-excitation

process is shown in the figure below.

The

curve A is the no load magnetisation curve and line B represent the current

through the capacitor. E is the stator induced voltage per phase of the line.

The capacitor supplies the necessary reactive current for excitation.

§ DC Dynamic Braking: In this method, the stator

of induction is connected across the DC supply. The method for getting DC

supply with the help of a diode bridge is shown in the figure below.

The

direct current flow through the stator produces a stationary magnetic field,

and the motion of the rotor in this field produces induces voltage in the

stationary windings. The machine therefore works as a generator and the

generated energy is dissipated in the rotor circuit resistance, thus giving the

dynamic winding.

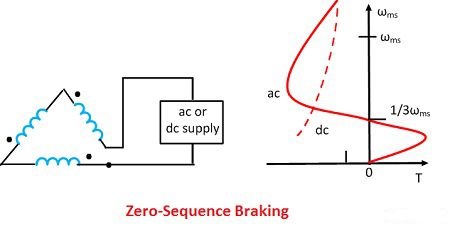

§ Zero Sequence Braking : In this braking, the three

phases of the stator are connected in series across either a single AC or DC

source. Such type of connection is known as zero sequence connection because

the current in all the three phases is co-phase. The nature of speed-torque

curve for AC and DC supply is shown in the figure below.

With

the AC supply, the braking could be used only up to one-third of

synchronous speed. The braking torque produces by this connection are

considerable larger than motoring. With DC supply braking is available the

entire speed range and the braking are essential a dynamic braking as all the

generated energy is wasted into rotor resistance.

For induction motor both AC or DC breaks are used. Below photo shows induction motor with break assembly :

No comments:

Post a Comment